Battling the Elements: FirmeCrete’s Performance in Extreme Winter Weather

I care more about this than most. I grew up skateboarding in Minnesota, and so upon graduating I immediately moved to Southern California where the pavement was actually smooth. Thirty years later, now based in Texas, my concrete career rarely involved freeze-thaw concerns—until I took on the challenge of creating a finish that could handle the brutal Midwest winters. This set me on a mission to uncover what really worked and what science still hadn’t fully answered.

I partnered with American Engineering Testing, Inc. in St. Paul MN (less than 5 miles from where I was born) with 24 slabs testing to find a correlation across 4 variables: air-entrainment, internal waterproofing admixtures, water-to-cement-ratio, and of course coated with FirmeCrete or not. Air Entraining admixtures have been the standard, so we casted slabs with and without AE-90 from Master Builder Solutions. Next, high-end Minnesotan installers like Hardline Concrete & Masonry told us that mixes with internal waterproofing admixtures were the best, so we cast slabs with 300L also from Master Builder Solutions. The rep from Master Builder Solutions said the ideal thing was a combination of those two, so we cast slabs with both AE-90 and 300L. I know that in the real world, w/c ratios often end up higher than the spec and worse, so we cast slabs with all the aforementioned permutations with both 0.4 and 0.7 w/c. Finally, half of each of those castings was coated with FirmeCrete, and half left uncoated.

All this was because we feared that a coated surface would perform in proportion to the quality of the substrate. I’ve managed over 4,000 decorative concrete projects in my career, so I’ve seen more than a few things go wrong. There are usually shades of quality and responsibility: things are rarely done 100% right, and some things are more critical to success than others. I imagined that we would discover the ideal way to make cast-in-place concrete resist freeze-thaw and that those coated slabs would perform very well and the lesser solutions – especially the slabs with poor w/c ratios would perform proportionally poorly. That is, I imagined parallel curves of performance where the coated slabs performed better or worse depending on the quality of the concrete beneath the coating.

Many of my conjectures were confirmed. Good w/c is completely correlated to performance. Air entrainment helps. Internal waterproofing helps. No surprises there. I expected the FirmeCrete coated samples to perform well because the sand used is very hard, it’s polymer-modified, and it’s porous enough to accept an impregnating sealer better than anything I can think of. They did perform well.

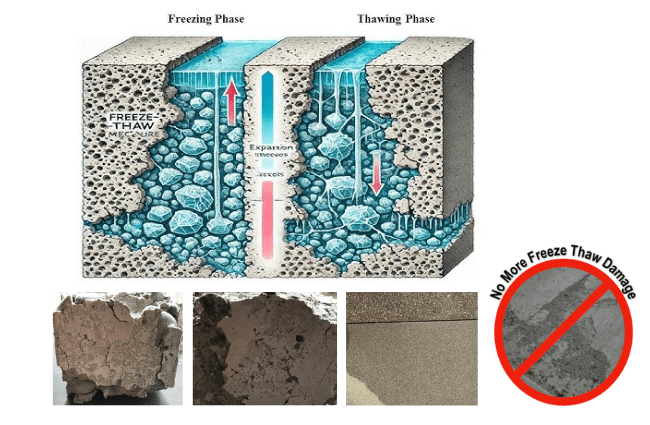

What I was positively shocked by was how much freeze/thaw resistance was improved by the coating. Slabs that completely failed – described as “Severe scaling (coarse aggregate visible over the entire surface)” – in less than 5 cycles without FirmeCrete made it 50 cycles with no scaling. I mean there wasn’t a curve of performance data that paralleled the data curve of the substrate. There was just a straight line of nearly perfect performance for every slab coated with FirmeCrete.

Attached is a PDF from American Engineering Testing, Inc. and my notes from the creation of the slab.

Notes from April, 2024 Castings

In hindsight, I think my w/c ratios of the test slabs were probably higher than intended. I neglected to kiln-dry the sand used and account for that lost weight when weighing the water. Since all of the slabs were cast with the same sand on the same day, the findings still seem deductively valid. I think that’s important to note though. Further, it’s reasonable to presume that very dense slabs coated with FirmeCrete would perform as well as less dense since there was no correlation between the coated slabs with different w/c ratios.

Additionally, I think it’s appropriate to note that these slabs’ finishings weren’t as good as one could expect in the field.

The lab required the slabs to be 3” by 9” by 8”, so the finishing was done entirely with a margin trowel by a finisher lacking any ACI certification. Again, the findings of this study do not seem undermined by this.

Cory Hanneman

![]()